Products Search

Products Categories

Company News

- 10-29Major brands in the color steel plate industry staged cross-border "dramas"

- 10-29The four major strategies will constitute the key factors for the modern color steel plate industry

- 10-29Grasping the trend of consumer upgrading: color steel plate enterprises understand consumer thinking

- 10-29What is the development direction of color steel plate enterprises in the era of "quality consu

- 10-29New trends in the color steel plate market:Industry reshuffle intensifies

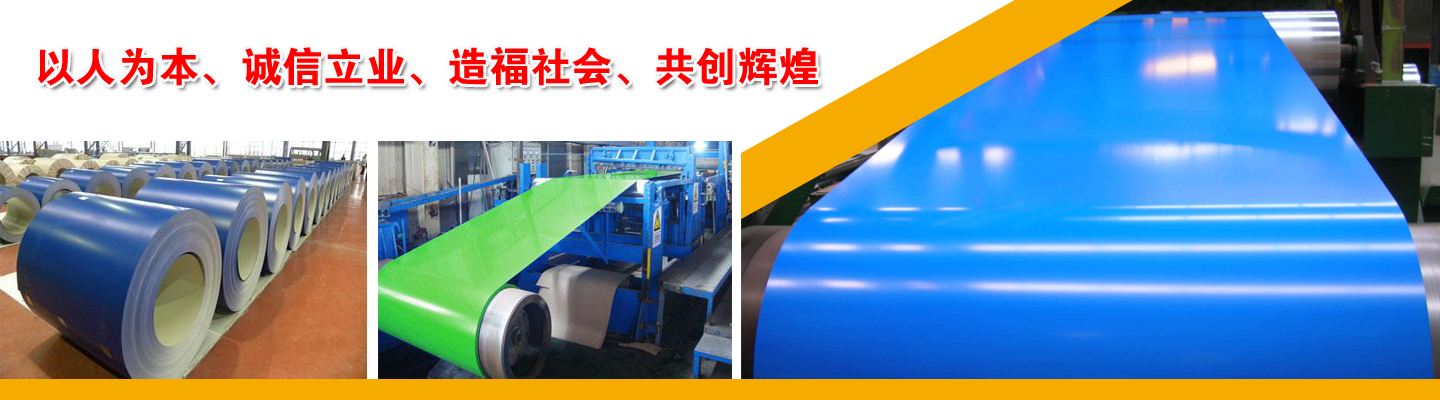

Color steel plate manufacturer, PVC coil material

Detailed introduction

| Scope of use | Architectural decoration | material quality | colour steel |

|---|---|---|---|

| purpose | building | Type | composite material |

| Characteristics | Strong weather resistance and bright color |

What is the reason for the phenomenon of paint explosion during the application of color steel plates

Whether in the construction industry, shipbuilding industry, furniture industry, or electrical industry, the presence of color steel plates can be seen, and at the same time, the development of Shandong color steel plates is constantly being innovated. Although the performance of color steel plates is excellent, there may be some problems in specific situations. For example, paint explosion on color steel plates is a common phenomenon, and any phenomenon has its reasons and principles. Understanding these can help better think of solutions when problems occur on color steel plates. Today, the editor will introduce the reasons for paint explosion on color steel plates.

1. When preparing the tank, add passivation solution first and then water. Due to the density issue of the passivation solution, for example, when the density of the passivation solution is higher than that of water, it can cause uneven mixing of raw materials, resulting in poor adhesion between the passivation layer and the substrate, which is very easy to cause paint explosion on the surface of the color steel plate.

2. There is also a production process regulation for passivation plate temperature that requires inspection every 2 hours, because the staff of the color steel plate manufacturer did not regularly track the passivation plate temperature during the inspection. Especially in winter, there is a significant temperature change within 2 hours, which ultimately leads to the failure of the color steel plate and the occurrence of scratches and paint peeling during molding.

During the production process of color steel plates, there is dust on the export inspection mirror and some rollers, which directly affects the surface quality of the color steel plates. Perhaps it may not show up at the beginning, but once the time is long or exposed to sunlight, the phenomenon of paint explosion will occur.

Color steel plate is a very thin steel plate with organic color coating. The wall panels and roof panels commonly used in activity rooms are used as fences on roadsides and construction sites. Shandong color steel plate manufacturers say that in recent years, with the development of the activity room industry, the demand for color steel plates for activity room materials has also increased.